Products

Automotive and industrial gaskets with wide range of application.

Mass and custom unit production using presses, laser and water jet.

Products made of various materials which are used in many industries.

Technology

and Services

Modern pressing plant with tool workshop equipped with eccentric and high-speed machines. Our products meet the requirements of ISO 9001:2016.

Thanks to the combination of these technologies we can process wide range of materials. Products can be later bend or formed based on customer's demand.

Die cutting has maximal time efficiency while CNC plotter cutting has high material utilization. Technology selection is based on customer's specification.

We are Kalina

In KALINA industries s.r.o. we produce seals and industrial components for automotive, engineering, agriculture, food, construction, chemical industry, water supply, energy and pharmacy.

Our company dates back to 1990, when Jan Kalina started manufacturing products in the basement of his family house in Zlín.

Thanks to experience, tradition and a responsible approach, we supply products to customers in the Czech Republic and the European Union.

We do it how it should be done

We manufacture mass and unit products with precision.

Our goal is to be reliable and flexible partner for our customers and employees. Our company policy is to develop, manufacture and deliver quality and ecologically friendly parts to every industrial branch.

High number of qualified and skilled workers combined with modern technologies is our great advantage. Thus it is possible to deal with customer's request quickly and professionally while maintaining low-price.

Products are quality checked from order assigment to expedition to customer. We follow ISO 9001 and ISO 14001 requirements and use HELIOS system in Inuvio version.

Based on

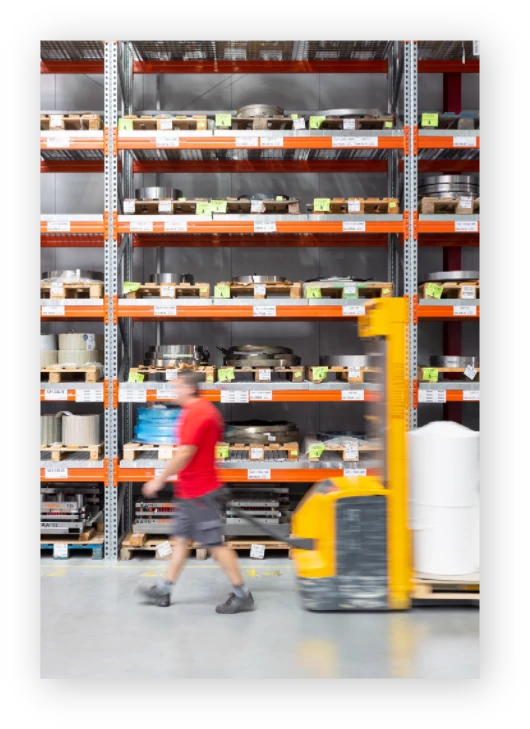

Wide range of materials on stock together with modern technologies enables even immediate production to meet the needs of our customers.

High-end materials, precise technologies, custom made tools and quality according to ISO 9001:2016 give our customers certainty.

Thanks to our rich experience and advanced equipment we are able to design the most optimal manufacturing process with regard to price.

More than 30 years of experience combined with high number of long-term customers attests to the quality of our services and products.

News

Career