Metal Pressing Plant and Tool Workshop

Metal Pressing Plant and Tool Workshop

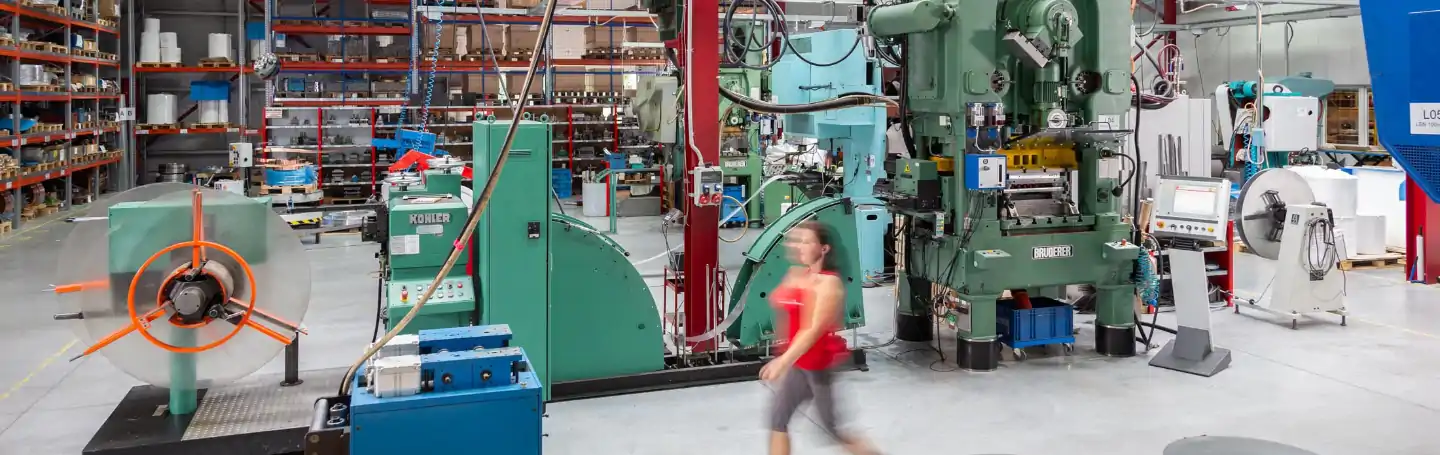

Modern equipment of pressing plant with tool workshop enables the production of small and big series of pressed metal parts in short time. Pressing plant contains high-speed Bruderer and eccentric presses with tonnage of 5-250 tons cold stamping. Toolshop allows us to make tools based of customer's demand. These workplaces are run by qualified workers with two decades of experience.

We value indiviadual approach towards each inquiry of our customers. Based on telephone, e-mail or personal communication, we create price calculation including all details about price. The use of modern information systems for work organization allows us to commence production as soon as possible. Quality measurement of our products is done by optical measuring device Vertex 311 HM. Measurements are fast and precise. Each order has its own barcode thanks to which we easily monitor all information about its associated product. Repeated production is easily done because production plan and data are saved in our database.

Quality is ensured by high production standarts and skilled personnel. We fulfill the standart of automotive industry including its measuring requirements and quality check. KALINA Industries is certified according to ISO 9001. Based on the requirement of our customers, we can produced parts in accordance with IATF 16949 and VDA standarts.