Stamping

Stamping

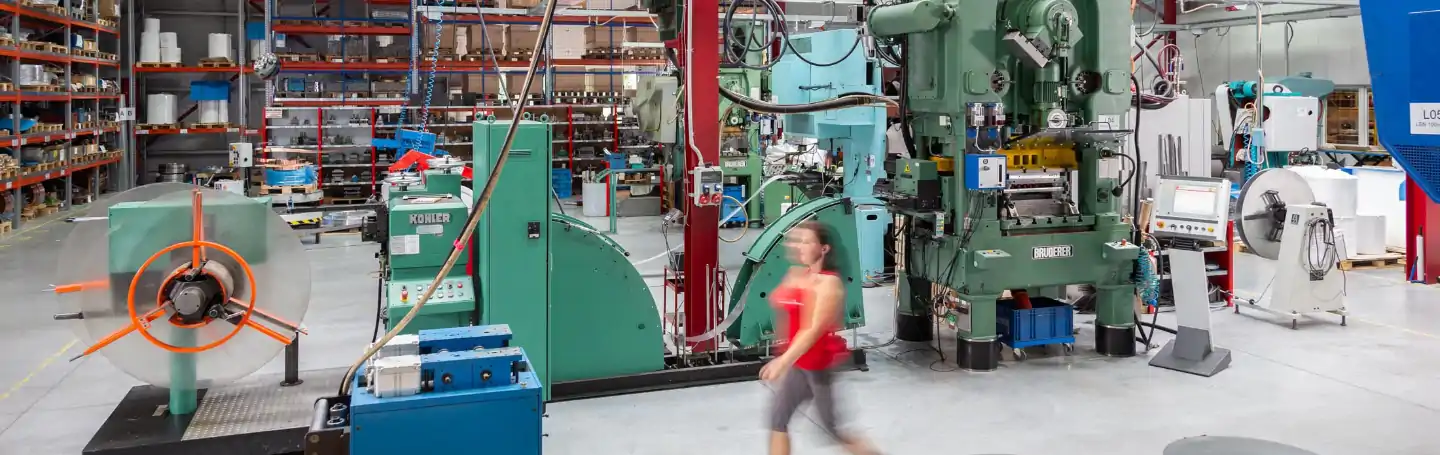

Small and large series of metal stampings can be produced in a short time thanks to the modernised technical equipment of the press shop and tool workshop.

In addition to our own production programme of standard parts, we also press parts for customers in the automotive, mechanical engineering, construction, electrical engineering, food processing and chemical industries.

Tool manufacturing:

An in-house design tool workshop allows us to respond quickly to customer requirements. With regard to serial production, the design of the press tools and the technological process are always created individually. However, we are also able to manufacture products with the use of tools supplied by the customer.

Our technology:

The press shop uses eccentric presses from 5 to 250 tonnes LEN and Bruderer high-speed presses from 25 to 80 tonnes for the actual production of parts (sheet metal stamping).

Quality control:

The long-established ISO 9001 system ensures quality control throughout the process, from product order to production and delivery to the customer. If required by the customer, product sampling can also be carried out in accordance with VDA or PPAP. We carry out inspection and measurement according to the customer's standard requirements for deliveries to the automotive industry.