Laser cutting, water jet cutting, bending and forming

Laser cutting, water jet cutting, bending and forming

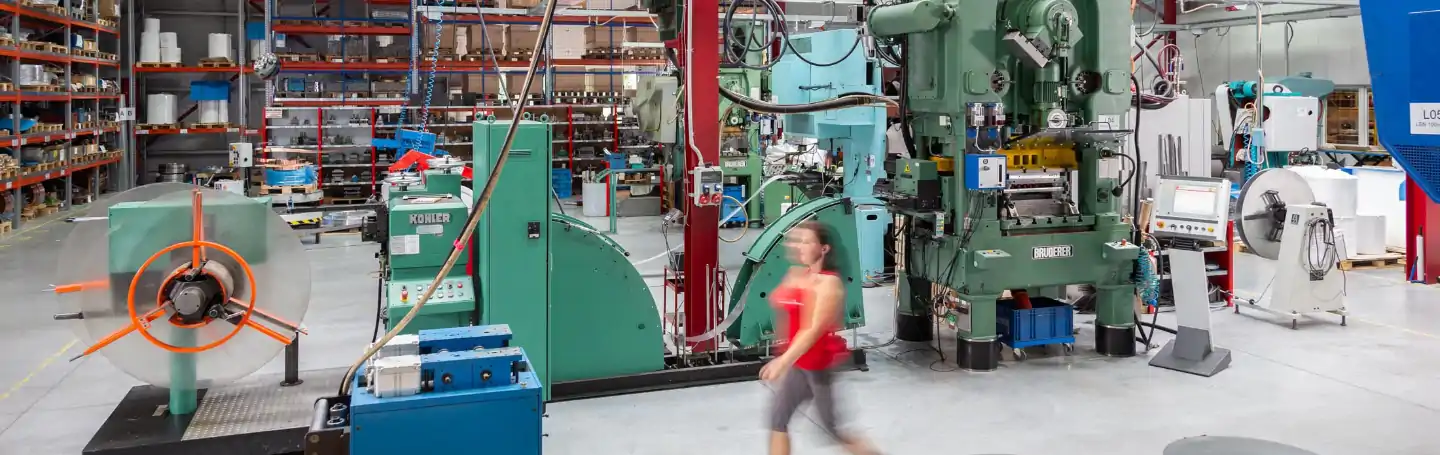

The considerable interest expressed by customers in our services provides a solid foundation for the ongoing growth of this modern department. The main goal is to ensure fast and high quality production. Subsequently, the cut parts undergo processing in line with customer specifications. The most common subsequent operations include bending, pressing and thread drilling. The combination of our modern technology and experienced team guarantees that every product meets the highest standards of quality and precision.

Laser cutting:

Our staff and modern machines provide high precision and speed in processing a variety of materials. This technology is ideal for the production of highly detailed and complex shapes, offering a wide range of applications across a variety of industries. The laser has a maximum power output of 8 kW.

Waterjet cutting:

The water jet cutting process is a highly precise and gentle method of cutting that does not affect the thermal properties of the material itself. This technology is suitable for cutting a wide range of materials, including metals, plastics, composites and ceramics. For harder materials, cutting is performed with the assistance of an abrasive.

CNC bending:

We offer metal bending and forming using a press brake, which allows for precise and high quality processing of various metal parts. This type of sheet metal processing is common after laser or water jet cutting.